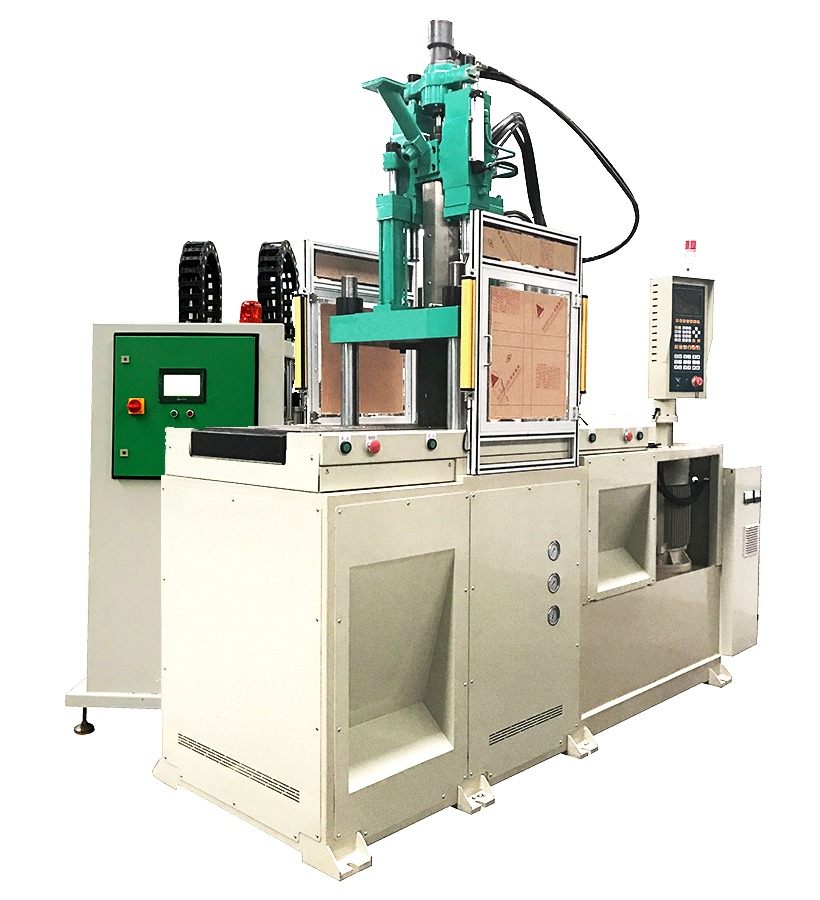

In the world of manufacturing, precision and flexibility are key to producing high-quality silicone rubber products. Hommar, a leading plastic mold machine manufacturer, introduces the Silicone Rubber Injection Machine, designed to meet the exacting standards of modern production environments. Combining advanced technology with robust engineering, Hommar's machine is ideal for a wide range of applications, from automotive to medical devices. This article delves into the features and benefits of the Silicone Rubber Injection Machine and highlights why it stands out in the market.

High Precision

The Silicone Rubber Injection Machine by Hommar is engineered for high precision, ensuring that each product meets exact specifications. This precision is crucial for applications requiring tight tolerances and detailed designs. Our advanced R&D team has integrated cutting-edge technology to achieve the highest levels of accuracy, making this machine a top choice for manufacturers who prioritize quality.

Versatility and Flexibility

One of the standout features of Hommar’s machine is its versatility. It can handle a variety of silicone rubber formulations and produce a wide range of products. Whether you are manufacturing components for the automotive industry, medical devices, or consumer goods, this machine provides the flexibility needed to adapt to different production requirements. The ability to quickly switch between molds and adjust settings enhances operational efficiency and reduces downtime.

Material Compatibility

Designed to work with various types of silicone rubber.

Injection Precision

Advanced control systems ensure precise injection, reducing material waste.

Production Speed

High-speed operation for efficient mass production.

User Interface

Intuitive control panel for easy operation and minimal training requirements.

Customization Options

Available for OEM/ODM services to meet specific client needs.

At Hommar, we understand that each client has unique requirements. That's why we offer comprehensive OEM/ODM services to customize the Silicone Rubber Injection Machine according to your specific needs. Our experienced design team collaborates closely with clients to develop tailored solutions, ensuring optimal performance for various applications. This customization ensures that each machine delivers the best possible results for its intended use.

As a leading plastic mold machine manufacturer, Hommar is committed to providing exceptional customer support and service. Our dedicated team of technicians is available to assist with installation, training, and maintenance, ensuring that your Silicone Rubber Injection Machine operates at peak efficiency. Additionally, we offer a range of after-sales services, including spare parts supply and technical support, to keep your operations running smoothly.

One of the key advantages of Hommar's Silicone Rubber Injection Machine is its excellent cost performance. By combining high precision, durability, and versatility, this machine offers significant value for manufacturers and suppliers. Its efficient operation reduces production costs, while its robust design minimizes maintenance expenses, making it a cost-effective investment for any production facility.

Automotive Industry

The automotive industry requires components that meet stringent quality standards and withstand harsh conditions. Hommar's Silicone Rubber Injection Machine is ideal for producing gaskets, seals, and other automotive parts with high precision and durability.

Medical Devices

Precision is critical in the medical industry, where silicone rubber is used to manufacture various devices and components. This machine ensures that each part is produced with the utmost accuracy, meeting the rigorous standards of the medical field.

Consumer Goods

From kitchenware to electronics, silicone rubber is a popular material for consumer goods. Hommar’s machine provides the flexibility to produce a wide range of products, catering to different market needs.

Hommar's Silicone Rubber Injection Machine is the ultimate solution for manufacturers seeking precision and flexibility in their production processes. With advanced technology, robust design, and comprehensive customization options, this machine is perfect for various applications, from automotive to medical devices and consumer goods. Supported by excellent cost performance and outstanding customer service, Hommar stands out as a top choice for silicone rubber injection molding. For more information or to place an order, please contact Hommar today.